Sheetmetal Fabrication and Engineering

About

our company

Vectorfab is a small, specialised sheet metal fabrication workshop based in the heart of Christchurch. We focus on turret punching, precision CNC folding, and high-quality welding for customers who value accuracy, reliability, and clear communication.

Built from the ground up VectorFab was created to serve businesses that need dependable parts without the overheads, delays, or minimums often associated with larger shops. Being small allows us to stay hands-on with every job, maintain tight tolerances, and adapt quickly to changing requirements.

We specialise in short to medium production runs, one-off components, and repeat work where consistency matters. From flat patterns through to finished assemblies, every part is approached with a practical manufacturing mindset designed to work, fit, and last.

At VectorFab, we take pride in honest workmanship, realistic lead times, and doing things right the first time. Whether you’re a local business needing ongoing support or a one-off job that needs careful attention, you’ll deal directly with the person making your parts.

Sheetmetal Folding

Vectorfab offers high-precision CNC press brake folding for sheet metal components requiring accurate bends, clean finishes, and consistent repeatability. Our folding services are ideal for everything from one-off custom parts through to small and medium production runs.

Using modern CNC press brake equipment, we ensure tight tolerances, accurate bend angles, and repeatable results across every job. Whether your part is simple or complex, we take the time to get the setup right because accuracy at the folding stage is critical to how parts fit, assemble, and perform in the real world.

Our press brake capabilities include:

Precise and repeatable CNC folding up to 2550mm long

Consistent bend angles and tight tolerances

Complex multi-bend components

Aluminium, mild steel, and stainless steel up to 6mm

Prototypes, one-offs, and short-to-medium production runs

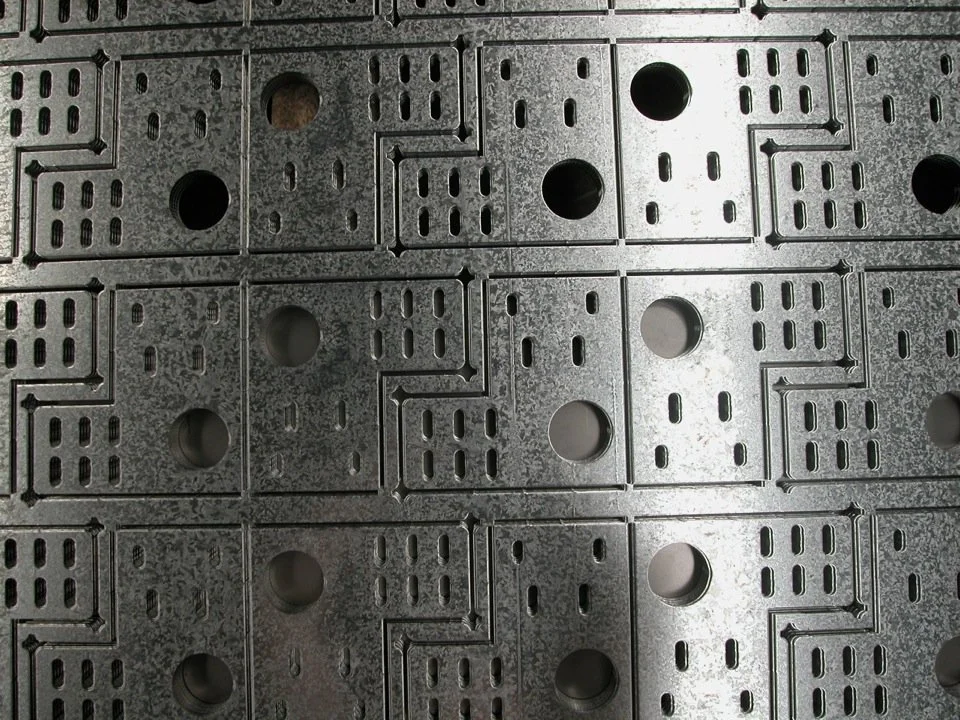

Turret Punching

We provide precision CNC turret punching for fast, accurate production of sheet metal components. Turret punching is an efficient and cost-effective solution for cutting, forming, and perforating sheet metal, particularly for repeat parts and short-to-medium production runs.

Our turret punching capabilities allow us to produce clean, consistent parts with tight repeatable tolerances.

What we offer:

Rapid turnaround on small to medium batch jobs

Complex hole patterns, slots, and cut-outs

Forming features including louvers, knock-outs, and embosses

Mild steel, stainless steel, and aluminium up to 3mm thick 1250x3000mm

Why turret punching?

Turret punching is ideal where speed, repeatability, and cost control matter. Compared to laser cutting, it can be more economical for parts with a high number of holes or formed features, making it a great choice for enclosures, brackets, panels, electrical cabinets, and general sheet metal components.

We work closely from drawings through to finished parts, ensuring your components are manufactured efficiently, accurately, and ready for folding, welding, or finishing.

Welding

Vectorfab provides high-quality TIG and MIG welding for sheet metal and light fabrication work, delivering strong, clean, and consistent welds across a wide range of applications. We specialise in welding components that require accuracy, good appearance, and dependable structural integrity.

Our TIG welding is ideal for thinner materials and applications where precision and finish matter. MIG welding is used where strength, efficiency, and repeatability are key, making it well suited to mild steel fabrication and structural assemblies.

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly.

For more accurate quotations and pricings please include any drawings, dxf’s and or pictures.